A Paradigm Shift

Modern maintenance strategies have undergone a radical transformation, moving from reactive approaches to intelligent foresight. Rather than waiting for equipment to fail or following rigid schedules, today's systems harness data-driven insights to foresee potential issues. This forward-thinking methodology helps businesses streamline operations while extending machinery lifecycles.

Sophisticated monitoring systems now detect minute operational deviations by processing continuous streams of sensor data, providing actionable warnings long before critical failures occur. Such early intervention capabilities create substantial financial benefits and operational improvements across industries.

Data Collection and Analysis

The foundation of effective maintenance prediction lies in comprehensive data gathering. Engineers strategically place monitoring devices on vital equipment to track essential metrics including movement patterns, thermal readings, pressure changes, and electrical consumption. Advanced computational models then transform this raw information into meaningful predictions about equipment health.

Algorithm Selection and Training

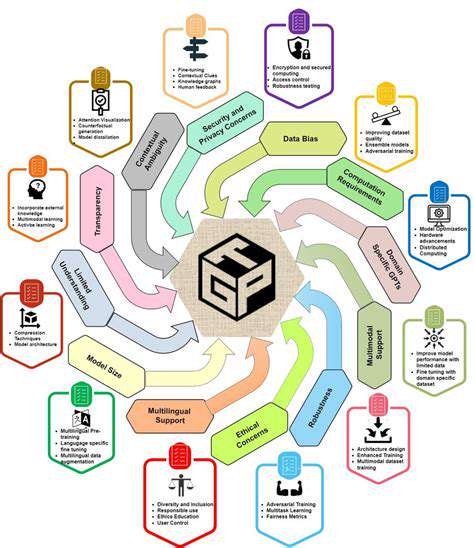

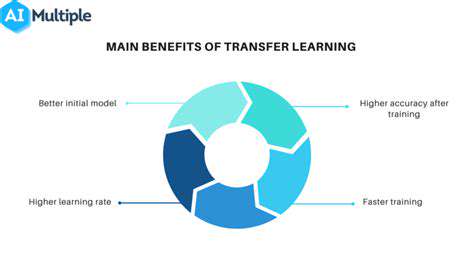

Choosing the right analytical approach makes all the difference. Maintenance systems incorporate various computational techniques – from machine learning frameworks to statistical models – each selected based on specific operational requirements. These systems undergo extensive training using historical operational records to ensure dependable performance when predicting future equipment needs.

The reliability of maintenance forecasts depends entirely on both the volume and precision of the training data. Incomplete or inaccurate datasets inevitably lead to flawed predictions and inefficient maintenance planning.

Maintenance Optimization and Cost Reduction

Anticipatory maintenance strategies offer remarkable opportunities for cost efficiency. By predicting equipment needs in advance, companies can schedule service during naturally slow periods, maintaining production continuity while minimizing financial impacts. This strategic approach dramatically decreases emergency repair expenses and associated operational losses.

Business Value and ROI

Investment in predictive systems delivers measurable financial returns. The combined benefits of reduced operational interruptions, lower repair expenses, extended equipment life, and improved efficiency create compelling business cases for adoption. While implementation requires upfront investment, the long-term financial and operational advantages typically justify the initial expenditure several times over.

Integration of AI for Enhanced Safety and Compliance

AI-Powered Real-Time Monitoring

Modern robotic systems incorporate continuous oversight capabilities that scrutinize every operational aspect. This vigilant monitoring instantly detects and addresses potential safety concerns, from mechanical irregularities to procedural deviations, elevating overall safety standards while ensuring product consistency.

The system's anticipatory capabilities prove particularly valuable. When detecting abnormal equipment conditions – like atypical mechanical wear – automated alerts enable preemptive intervention, preventing operational failures before they compromise safety or productivity.

Predictive Maintenance for Equipment Longevity

Advanced analysis of operational history allows these systems to forecast potential mechanical issues. By recognizing patterns in performance metrics, the technology can schedule maintenance before problems escalate, ensuring uninterrupted operation while maximizing equipment service life.

Automated Compliance Verification

Intelligent systems automatically validate adherence to all regulatory requirements. Continuous process monitoring guarantees precise product handling according to specifications, eliminating compliance risks while minimizing potential human oversight in critical operations.

Enhanced Security Measures

Sophisticated access control mechanisms integrate seamlessly with operational systems. Real-time authentication protocols prevent unauthorized access, creating robust protection for sensitive materials and processes while maintaining operational integrity.

Improved Product Quality and Consistency

Precision control systems continuously optimize operational parameters. By dynamically adjusting variables like operational speed and environmental conditions, the technology ensures uniform product quality across all outputs, meeting exact specifications every time.

Data-Driven Decision Making for Process Optimization

The system's comprehensive data collection enables continuous operational refinement. Analysis of performance metrics and output quality identifies improvement opportunities, facilitating data-informed enhancements that boost efficiency while controlling costs.

Reduced Human Error and Increased Efficiency

Automation significantly decreases operational risks associated with manual processes. By eliminating human variability in critical procedures, these systems achieve unprecedented levels of operational reliability while allowing personnel to focus on higher-value responsibilities.