Improving Quality and Enhancing Responsiveness

Improving Quality Through Enhanced Processes

Implementing robust quality control measures throughout the production pipeline is crucial for delivering high-quality products and services. This involves establishing clear standards and procedures for each stage, from raw material sourcing to final product inspection. By consistently adhering to these standards, we can minimize errors and defects, ultimately leading to greater customer satisfaction. Furthermore, continuous monitoring and evaluation of these processes are essential to identify areas for improvement and maintain a high level of quality over time.

Streamlining Operations for Efficiency

Optimizing workflows and processes is paramount to enhancing overall efficiency. This involves analyzing current operational procedures to identify bottlenecks and inefficiencies. By implementing streamlined processes, we can reduce wasted time and resources, leading to significant cost savings. This streamlining will also enable us to deliver products and services more quickly, enhancing our responsiveness to market demands.

Enhancing Customer Experience

Delivering exceptional customer experiences is critical for long-term success. This means actively listening to customer feedback and incorporating their suggestions into our products and services. Providing clear and concise communication channels, responsive support, and personalized interactions will elevate the overall customer experience and foster loyalty. A positive customer experience is not just about the product itself, but also about the entire interaction with the company.

Investing in Training and Development

Investing in employee training and development is essential for maintaining a skilled and motivated workforce. Providing opportunities for continuous learning and skill enhancement empowers employees to perform their tasks more effectively. This leads to improved product quality, increased efficiency, and a more positive work environment. By fostering a culture of continuous learning, we can ensure that our team is equipped with the skills needed to adapt to evolving market conditions.

Leveraging Technology for Innovation

Embracing technological advancements is key to fostering innovation and driving improvements across various aspects of our operations. This includes integrating new tools and technologies to streamline processes, automate tasks, and enhance data analysis capabilities. Implementing data-driven decision-making strategies, based on insights gleaned from technological tools, will also allow us to make informed choices that lead to better outcomes.

Fostering Collaboration and Communication

Strong collaboration and communication are vital for success. Encouraging teamwork and open communication channels between departments and teams will foster a more cohesive and productive work environment. This will allow for better knowledge sharing, efficient problem-solving, and a more unified approach to achieving our goals. Clearly defined roles and responsibilities, combined with transparent communication, are essential to a successful collaborative environment. Effective communication bridges the gaps between different teams, facilitating seamless workflows and reducing the risk of misunderstandings.

The Future of Manufacturing: Embracing the Smart Factory Paradigm

The Rise of Automation and Data-Driven Decision Making

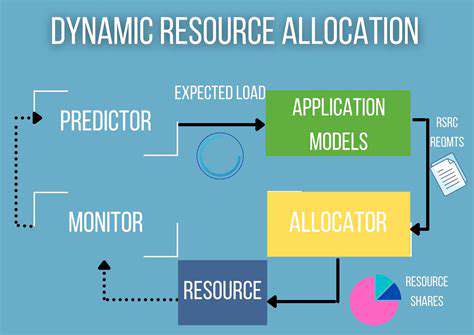

The smart factory paradigm is fundamentally changing how manufacturing operates. Automation is no longer a futuristic concept but a critical component of modern production lines. Sophisticated robotics and automated guided vehicles (AGVs) are streamlining processes, optimizing workflows, and significantly increasing output. This shift towards automation not only boosts efficiency but also reduces human error and improves safety within the factory environment. Furthermore, the integration of advanced sensors and machine learning algorithms allows for real-time data collection and analysis, enabling manufacturers to make data-driven decisions regarding production, maintenance, and resource allocation.

Data analytics plays a crucial role in this transformation. By analyzing vast amounts of data generated from various sources within the factory, manufacturers can gain valuable insights into production patterns, identify potential bottlenecks, and predict equipment failures. This proactive approach to maintenance minimizes downtime and reduces operational costs, fostering a more agile and responsive manufacturing process.

Enhanced Collaboration and Communication Through Connectivity

A key aspect of the smart factory is the seamless integration of various systems and departments. Real-time communication between machines, robots, and human operators is essential for efficient collaboration. This connectivity allows for a better understanding of the entire production process, enabling faster problem-solving and improved decision-making across the entire organization. The ability to share data instantaneously enhances communication and collaboration among different teams, fostering a more connected and integrated work environment.

The interconnected nature of smart factories also facilitates better communication between manufacturers and their supply chains. This enhanced visibility and transparency into the entire production process enables more efficient supply chain management. Predictive modeling and real-time data sharing minimize delays and improve responsiveness, leading to more efficient and reliable supply chains. This connectivity is not just about internal communication; it also extends to external partners, strengthening relationships and fostering collaborative innovation.

Optimizing Resource Utilization and Sustainability

Smart factories are designed to optimize the utilization of resources, contributing to a more sustainable approach to manufacturing. Real-time monitoring of energy consumption and material usage allows for identifying areas for improvement and implementing solutions to reduce waste. The integration of renewable energy sources can further enhance the environmental sustainability of the manufacturing process. By tracking and analyzing resource usage, manufacturers can identify inefficiencies and implement strategies to reduce waste, conserve energy, and minimize their environmental footprint.

Beyond energy and materials, smart factories also optimize the utilization of human capital. By automating repetitive tasks, the focus shifts towards higher-value activities and skilled labor. This promotes worker satisfaction and empowerment while simultaneously enhancing productivity. This shift towards skill-based roles empowers workers and fosters a more engaged workforce, leading to increased job satisfaction and higher overall productivity. This focus on sustainability also extends to the entire lifecycle of products, promoting a circular economy model.

The Future of Work and Skill Development

The transition to smart factories necessitates a shift in the skills required of the workforce. Traditional manufacturing jobs are evolving to incorporate a greater emphasis on technology and data analysis. This means that workers need to develop new skills in areas like data interpretation, machine learning, and automation systems. To meet this evolving demand, educational institutions and companies must adapt their training programs to equip employees with the skills necessary for the future of manufacturing. This means fostering a culture of continuous learning and upskilling within the workforce to ensure they remain relevant and adaptable in a rapidly changing technological landscape.

The rise of smart factories signifies a fundamental change in the nature of work. Human workers will increasingly collaborate with machines, focusing on tasks that require creativity, critical thinking, and problem-solving skills. This shift in the workforce will require a new approach to training and development, emphasizing adaptability, digital literacy, and a willingness to embrace continuous learning. This evolution is crucial for both individuals and organizations to thrive in this new era of manufacturing.