The Foundation of IIoT in Modern Manufacturing

The Industrial Internet of Things (IIoT) is revolutionizing manufacturing processes by connecting machines, sensors, and devices across the factory floor. This connectivity allows for real-time data collection and analysis, enabling manufacturers to optimize operations, improve efficiency, and enhance overall productivity. This fundamental shift from isolated systems to a unified network of interconnected devices is the cornerstone of the connected factory. The ability to gather, process, and act upon data in real-time creates a dynamic feedback loop that drives continuous improvement within the production environment.

Early stages of IIoT implementation often focus on automating routine tasks, such as monitoring equipment health and predicting maintenance needs. However, the true potential of IIoT lies in its ability to foster a more holistic understanding of the entire production process. By connecting every aspect of the factory, from raw materials to finished goods, manufacturers gain a comprehensive view of their operations, enabling them to make more informed decisions and optimize their entire value chain.

Data-Driven Decision Making in Connected Factories

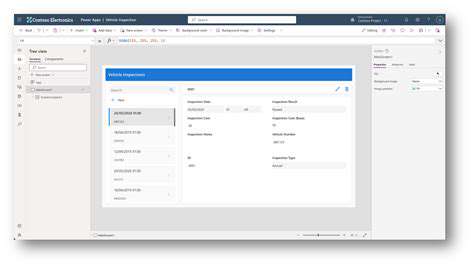

A key benefit of IIoT is the wealth of data it generates. This data, collected from sensors, machines, and other connected devices, provides valuable insights into various aspects of manufacturing operations. Analyzing this data allows manufacturers to identify patterns, predict potential issues, and make data-driven decisions. Real-time insights, derived from IIoT-enabled dashboards and analytics tools, provide a competitive edge by empowering proactive adjustments to production processes, leading to reduced downtime, increased output, and optimized resource utilization.

From predictive maintenance to optimized logistics, the ability to analyze real-time data streams empowers manufacturers to make informed decisions that impact every stage of the production cycle. This proactive approach minimizes disruptions, reduces costs, and ultimately, enhances profitability.

Improving Operational Efficiency Through Automation

Automation is a critical component of IIoT, enabling manufacturers to automate tasks, optimize processes, and streamline operations. IIoT facilitates automation by providing a robust platform for connecting and controlling automated systems across the entire production line. This level of integration allows for a more seamless and coordinated workflow, resulting in increased efficiency and reduced human error. The ability to automate repetitive tasks frees up human workers to focus on higher-level tasks, leading to improved productivity and a more engaged workforce.

The Future of IIoT: Emerging Trends and Challenges

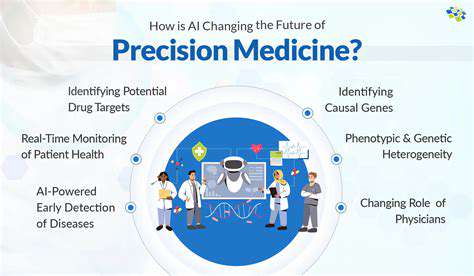

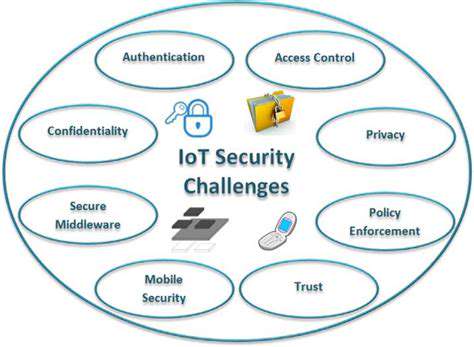

The future of IIoT in manufacturing is bright, with several emerging trends shaping its evolution. One notable trend is the increasing use of artificial intelligence (AI) and machine learning (ML) to analyze data and enhance decision-making. AI algorithms can identify patterns and anomalies in data, allowing for more accurate predictions and proactive responses to potential issues. However, challenges remain, including data security and the need for skilled personnel to manage and maintain these complex systems. Addressing these challenges is critical to unlocking the full potential of IIoT and ensuring its successful integration into modern manufacturing processes.

Enhanced Operational Efficiency and Productivity

Improving Real-Time Decision Making

Industrial IoT (IIoT) empowers real-time data collection and analysis across diverse industrial processes. This constant stream of data, from sensors embedded in machinery to production lines, allows for the immediate identification of anomalies, enabling swift corrective actions and preventing costly downtime. By providing a comprehensive view of the operational landscape, IIoT facilitates quicker responses to emerging issues, fostering a more agile and responsive industrial environment. This agility translates into significant cost savings and improved efficiency by minimizing production disruptions and maximizing resource utilization.

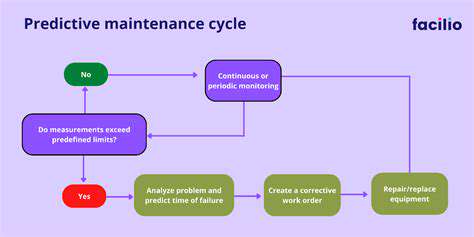

The ability to analyze data in real-time allows for predictive maintenance strategies. By identifying patterns in equipment performance, IIoT systems can predict potential failures, enabling proactive maintenance schedules. This approach reduces unexpected breakdowns, minimizes costly repairs, and maximizes equipment uptime, ultimately boosting overall operational efficiency and productivity.

Optimizing Resource Allocation

IIoT systems provide granular insights into resource consumption across various production stages. This detailed analysis enables optimized allocation of resources, including raw materials, energy, and personnel. By identifying areas of inefficiency and bottlenecks, IIoT facilitates the reallocation of resources to maximize output and minimize waste. This optimized resource management leads to significant cost reductions and enhances the overall productivity of industrial operations.

Real-time visibility into resource utilization allows for dynamic adjustments to production schedules and workflows. For example, if a particular machine experiences a surge in demand, IIoT systems can automatically adjust the allocation of resources to meet the increased demand, ensuring smooth operations and maximizing output. This flexibility is crucial for adapting to changing market conditions and maintaining a competitive edge in the industry.

Enhancing Safety and Compliance

Industrial IoT systems can significantly improve workplace safety by monitoring critical parameters in real-time. By detecting potential hazards and abnormalities, IIoT systems can alert personnel, thereby preventing accidents and injuries. This proactive safety approach minimizes the risk of accidents and ensures worker safety, ultimately reducing insurance costs and improving employee morale.

Moreover, IIoT systems can also assist in ensuring compliance with safety regulations and industry standards. By automating the monitoring and reporting of critical parameters, IIoT solutions streamline compliance processes, reducing the risk of penalties and ensuring that operations adhere to all relevant regulations. This focus on safety and compliance promotes a positive work environment and strengthens the company's reputation in the industry.

Improving Maintenance and Preventative Actions

IIoT facilitates predictive maintenance by analyzing equipment performance data to identify potential failures before they occur. This proactive approach minimizes downtime and reduces the need for costly emergency repairs. The insights gleaned from IIoT data allow for the scheduling of maintenance activities based on the actual needs of the equipment, rather than relying on arbitrary timetables. This precision leads to significant cost savings and improved equipment lifespan.

By collecting and analyzing data from various sources, IIoT enables a deeper understanding of equipment performance. The detailed insights provided by IIoT allow for the implementation of targeted maintenance strategies, improving the overall reliability and operational efficiency of industrial processes. This comprehensive approach to maintenance further optimizes the use of resources and reduces overall operational costs.

AI-powered chatbots are rapidly transforming customer service interactions, providing instant and 24/7 support. These sophisticated programs can handle a wide range of inquiries, from simple order tracking to complex technical issues. By leveraging natural language processing (NLP), chatbots can understand customer requests, answer questions accurately, and even resolve some issues autonomously, leading to significant efficiency gains and reduced wait times for customers. This shift towards automated support frees up human agents to focus on more complex and nuanced problems, resulting in a more personalized and effective customer experience.

Data-Driven Decision Making and Process Optimization

Understanding the Power of Data

Data-driven decision-making, a cornerstone of modern business strategies, is profoundly important in the context of Industrial IoT (IIoT). By leveraging data collected from interconnected industrial devices, organizations can gain a comprehensive understanding of their operations, identify areas for improvement, and ultimately optimize their processes. This data-rich environment allows for a deeper dive into performance metrics, enabling proactive problem-solving and a more agile approach to challenges.

The sheer volume and variety of data generated by IIoT systems are unprecedented. Harnessing this wealth of information is crucial for transforming insights into actionable strategies, leading to enhanced efficiency and profitability. Analyzing trends and patterns in this data is key to predicting future performance and proactively addressing potential issues.

Identifying Bottlenecks and inefficiencies

IIoT systems provide an unparalleled view into the inner workings of industrial processes. By monitoring real-time data streams from various machines and equipment, organizations can pinpoint bottlenecks and inefficiencies in their operations. This granular level of visibility allows for detailed analysis of production cycles, identifying areas where processes are lagging or where resources are being wasted.

For example, detecting anomalies in sensor readings or machine performance metrics can signal potential problems before they escalate into major disruptions. This proactive approach to problem-solving saves valuable time and resources, minimizing downtime and maximizing productivity.

Optimizing Production Processes

Data-driven insights from IIoT enable significant improvements in production efficiency. By analyzing the real-time performance of machinery and equipment, organizations can adjust parameters, optimize workflows, and fine-tune production processes to achieve higher output with less waste. This optimization can translate into substantial cost savings and increased profitability.

Moreover, IIoT data allows for predictive maintenance, enabling organizations to schedule maintenance activities proactively and prevent costly equipment failures. This approach reduces downtime, minimizes repair costs, and ensures continuous operation of critical machinery.

Improving Supply Chain Management

IIoT systems offer a robust framework for enhancing supply chain visibility and control. By connecting various points in the supply chain, from raw materials to finished goods, organizations gain a holistic view of the entire process. This real-time visibility enables proactive adjustments to inventory levels, minimizes delays, and enhances overall supply chain efficiency.

Data insights can be used to optimize transportation routes, predict demand fluctuations, and improve warehouse management. In turn, this results in reduced costs, improved delivery times, and enhanced customer satisfaction.

Real-Time Monitoring and Control

The real-time monitoring capabilities of IIoT systems are transformative for industrial processes. By providing instant feedback on equipment performance, organizations can make immediate adjustments to optimize processes, leading to more efficient operations and reduced waste. This level of control allows for dynamic responses to changing conditions, ensuring optimal performance under various circumstances.

Enhanced Security and Safety

A significant advantage of IIoT systems is their ability to enhance safety and security in industrial environments. By monitoring critical parameters and identifying potential hazards, organizations can implement preventive measures to mitigate risks. Real-time data analysis allows for early detection of abnormalities and facilitates swift responses to potential threats.

Moreover, IIoT-enabled security systems can help prevent unauthorized access to critical equipment and processes, safeguarding sensitive data and maintaining the integrity of industrial operations. This enhanced security posture is crucial in today's increasingly complex and demanding industrial landscape.

Security and Scalability: Addressing the Challenges of IIoT Implementation

Implementing Robust Security Measures

A robust security strategy is paramount for any modern application. Implementing multi-factor authentication (MFA) is crucial for protecting user accounts and sensitive data from unauthorized access. This adds an extra layer of security, requiring more than just a password to log in, making it significantly harder for attackers to gain access. Furthermore, regular security audits and penetration testing are essential to identify and address vulnerabilities before they can be exploited.

Employing encryption techniques for data both in transit and at rest is also vital. Strong encryption algorithms, combined with secure key management practices, are essential to protect sensitive information from potential breaches. This proactive approach ensures the confidentiality and integrity of data throughout its lifecycle.

Optimizing for Scalability

Scalability is essential for applications designed to handle growing user bases and increasing data volumes. A well-designed architecture should be adaptable to accommodate future growth without compromising performance. This involves choosing appropriate technologies that can handle high traffic loads and large datasets.

Employing cloud-based infrastructure can significantly enhance scalability. Cloud services offer the flexibility to dynamically adjust resources based on demand, ensuring optimal performance even during peak usage periods. This eliminates the need for significant upfront investment in hardware and allows for a more cost-effective approach to scalability.

Data Integrity and Validation

Maintaining data integrity and enforcing data validation rules are critical for preventing inconsistencies and errors. Robust validation checks at the database level can help prevent malicious input and ensure data accuracy. This proactive approach safeguards against data corruption and ensures the reliability of the application's data.

Implementing data integrity constraints, such as unique keys and foreign keys, is essential to maintain data consistency and avoid potential problems stemming from data inconsistencies.

Performance Monitoring and Tuning

Regular performance monitoring is crucial to identify bottlenecks and optimize application performance. Monitoring key metrics, such as response times and resource utilization, allows for proactive identification and resolution of performance issues.

Tuning the application's architecture and codebase is vital to optimize performance for diverse workloads. This involves analyzing performance data and making adjustments to improve efficiency and responsiveness. This proactive approach ensures a seamless user experience and prevents performance degradation during peak usage periods.

Disaster Recovery and Business Continuity

A comprehensive disaster recovery plan is essential to ensure business continuity in the event of a system failure or major outage. Having a backup and recovery strategy in place is crucial for minimizing downtime and maintaining service availability. This proactive approach mitigates the impact of unexpected events and allows for a seamless transition to a recovery environment.

Security Auditing and Compliance

Regular security audits are critical for identifying and addressing vulnerabilities. Audits help ensure that the application adheres to industry standards and best practices for security. Thorough security audits can help prevent potential breaches and maintain the trust of users.

User Access Control and Authorization

Implementing a robust user access control and authorization system is crucial for managing user permissions and preventing unauthorized access to sensitive resources. A well-designed system ensures that only authorized users have access to specific data or functionalities. This approach reduces the risk of data breaches and protects the confidentiality of sensitive information.