Leveraging Data for Proactive Repairs

Data-Driven Insights for Predictive Maintenance

Analyzing historical maintenance records, operational data, and environmental factors allows for the identification of patterns and anomalies that predict potential equipment failures. This proactive approach enables organizations to schedule maintenance before breakdowns occur, minimizing downtime and maximizing equipment lifespan. Predictive maintenance strategies, based on data analysis, can lead to significant cost savings by preventing unexpected failures and reducing the need for emergency repairs. By understanding the underlying causes of equipment issues, preventative measures can be implemented to avoid recurring problems. This proactive approach fosters a culture of continuous improvement, enabling organizations to optimize their maintenance processes and improve overall operational efficiency.

Data-driven insights can be used to establish optimal maintenance schedules that are tailored to the specific needs of each piece of equipment. This personalized approach ensures that resources are allocated effectively, preventing unnecessary maintenance and maximizing the productive output of the equipment. The analysis of real-time data streams, combined with historical trends, provides a comprehensive understanding of equipment performance, enabling the identification of potential failures before they impact production. This foresight helps in achieving consistent and reliable equipment performance, eliminating costly disruptions and increasing productivity.

Optimizing Maintenance Strategies with Data

Data analysis can provide valuable insights into the root causes of equipment failures, enabling organizations to implement targeted solutions and preventative measures. Understanding the factors contributing to breakdowns, like environmental conditions, operational loads, and material fatigue, allows for the development of more effective maintenance strategies. This approach minimizes the risk of future failures by addressing the underlying causes, rather than simply reacting to them.

Data-driven maintenance strategies can involve the implementation of condition monitoring systems that track key performance indicators (KPIs) in real-time. The continuous monitoring of these indicators allows for early detection of potential issues, enabling timely intervention and minimizing the impact on production. This proactive approach to maintenance translates into significant cost savings by avoiding costly repairs and preventing production disruptions.

Moreover, data analysis can help optimize maintenance resource allocation. By identifying patterns and trends in equipment failures, organizations can prioritize maintenance tasks and allocate resources effectively, ensuring that the most critical equipment receives the necessary attention. This data-driven approach can lead to improved efficiency and a more cost-effective maintenance program.

Improving Operational Efficiency through Proactive Repair

Proactive repair, facilitated by data-driven insights, allows organizations to significantly reduce downtime and improve overall operational efficiency. By anticipating potential equipment failures, maintenance teams can schedule repairs during off-peak hours or during planned shutdowns, minimizing the impact on production. This proactive approach allows for a more streamlined maintenance process, leading to greater operational efficiency.

Implementing data-driven strategies for proactive repair can lead to substantial cost savings by avoiding costly emergency repairs and minimizing lost production time. Predicting potential failures and scheduling repairs in advance can significantly reduce the financial burden associated with unplanned downtime. By leveraging data analysis, organizations can optimize their maintenance processes, resulting in a more sustainable and cost-effective approach to equipment management. This data-driven approach fosters a culture of continuous improvement, enabling organizations to optimize their maintenance processes and improve overall operational efficiency.

The Future of Smart Home Maintenance and Savings

Predictive Maintenance for Enhanced Efficiency

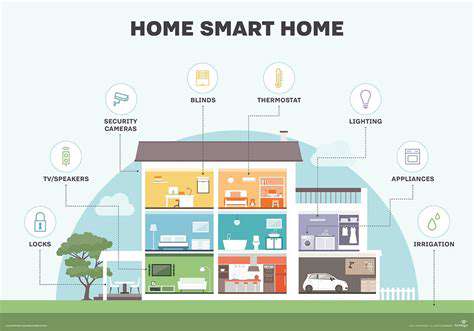

Smart home systems are rapidly evolving, moving beyond basic automation to incorporate advanced predictive maintenance capabilities. This innovative approach analyzes data from various connected devices within the home, like thermostats, appliances, and security systems, to identify potential issues before they escalate into costly repairs. Predictive maintenance algorithms identify patterns and anomalies in usage data, allowing homeowners to proactively address potential problems, reducing downtime and extending the lifespan of their appliances. This approach not only saves money on repair costs but also minimizes disruptions to daily routines, enhancing overall comfort and convenience.

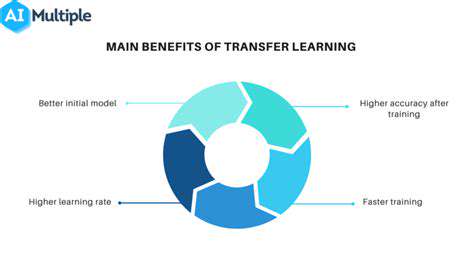

By anticipating and preventing breakdowns, homeowners can significantly reduce the need for emergency repairs. This proactive approach translates into substantial long-term savings, as frequent repairs and replacements are often more expensive than preventative measures. The integration of machine learning and artificial intelligence into these systems allows for increasingly sophisticated analysis, leading to even more accurate predictions and optimized maintenance schedules.

Real-Time Monitoring and Remote Access for Peace of Mind

The future of smart home maintenance involves seamless real-time monitoring and remote access capabilities. Homeowners can access detailed insights into their home's energy consumption, appliance performance, and security status from anywhere in the world. This access provides a comprehensive overview of the home's operational health, allowing for immediate intervention if any issues arise. This remote monitoring capability is particularly beneficial for homeowners who live far from their property or have elderly family members living at home.

Remote access empowers homeowners to address potential problems before they become critical. Imagine receiving a notification on your phone alerting you to a potential leak in the plumbing system, allowing you to take swift action to prevent further damage. This constant monitoring and proactive approach not only saves money but also enhances safety and peace of mind.

Further, real-time monitoring enables homeowners to optimize energy usage by adjusting settings remotely based on real-time data. This feature can lead to significant energy savings, contributing to a more sustainable lifestyle. The availability of remote access also fosters a deeper understanding of how the home operates, allowing homeowners to customize their environment for maximum comfort and efficiency.

Integration with IoT Devices and Data Analytics for Comprehensive Insights

The future of smart home maintenance is inextricably linked to the broader Internet of Things (IoT) ecosystem. Smart homes are increasingly equipped with a wide array of interconnected devices, generating a wealth of data that can be leveraged for comprehensive insights into home performance. This data analysis can identify patterns and trends in energy consumption, appliance usage, and security activity, providing valuable information to optimize maintenance schedules and reduce energy waste.

Advanced data analytics tools can identify anomalies and predict potential failures across various home systems. This capability allows homeowners to anticipate and prevent costly repairs, maximizing the lifespan of appliances and minimizing disruptions. Furthermore, the integration of IoT devices allows for more comprehensive control and automation of home systems, leading to greater efficiency and convenience.

By connecting various devices, the smart home can create a comprehensive view of its overall health. This holistic understanding of performance allows for proactive maintenance, leading to significant savings in energy costs and repair expenses. The ability to analyze aggregated data from multiple sources provides a deeper understanding of the home's needs, allowing homeowners to tailor their maintenance strategies for optimal performance and longevity.

The use of sophisticated algorithms can process this data to provide actionable insights. For example, a smart home system can detect subtle changes in appliance operation and flag them as potential issues, allowing the homeowner to address them before they become major problems. Furthermore, the system can adjust settings automatically, optimizing energy use and minimizing waste.

Sophisticated analytics can identify potential issues and alert homeowners in advance, enabling them to take preventive measures. This proactive approach dramatically reduces repair costs and keeps the home running smoothly and efficiently.