Revolutionizing Manufacturing Processes

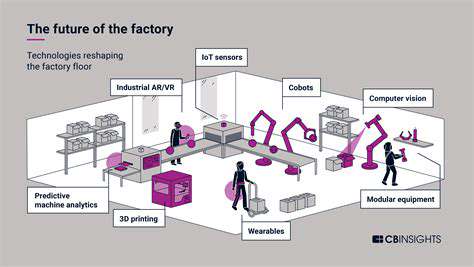

Transforming manufacturing industries involves a multifaceted approach, encompassing automation, data analytics, and innovative materials. Implementing advanced robotics and automation systems can significantly increase efficiency and reduce labor costs. This automation allows for 24/7 operation, minimizing downtime and maximizing output. By integrating real-time data analytics into manufacturing processes, companies can identify bottlenecks, predict equipment failures, and optimize production schedules for enhanced productivity and reduced waste.

The use of advanced materials and technologies, such as 3D printing and composites, is also reshaping manufacturing. These innovations enable the creation of customized and complex parts with reduced material usage, leading to lower production costs and improved product performance. The ability to produce intricate designs and personalized products is revolutionizing manufacturing's approach to design and production.

Enhancing Supply Chain Resilience

Modern supply chains face increasing complexities and disruptions, demanding robust strategies for resilience. This necessitates diversifying suppliers, implementing advanced forecasting models, and establishing redundant logistics networks. By diversifying supplier bases, companies can mitigate risks associated with single points of failure and ensure continued operations during unexpected events.

Implementing real-time tracking and visibility systems throughout the supply chain is crucial for proactive management of inventory levels, demand fluctuations, and potential disruptions. This allows for swift adjustments and improved response times to changing market conditions.

Improving Operational Efficiency through Technology

The integration of various technologies, including artificial intelligence (AI) and machine learning (ML), is fundamentally changing how manufacturing operations function. These technologies enable predictive maintenance, optimized resource allocation, and enhanced decision-making processes. AI-powered systems can analyze vast amounts of data to identify patterns and predict potential equipment failures, minimizing downtime and maximizing operational efficiency.

Moreover, machine learning algorithms can optimize resource allocation and production schedules, leading to increased output with reduced waste. These technologies empower companies to make data-driven decisions, leading to improved overall operational efficiency.

Driving Innovation and Sustainability

The future of manufacturing lies in embracing innovation and sustainability. This involves developing environmentally friendly production methods, utilizing renewable energy sources, and reducing waste throughout the entire process. Companies are increasingly adopting sustainable practices, recognizing that environmental responsibility is crucial for long-term success.

Furthermore, investing in research and development for new materials and technologies is essential for creating innovative products and processes. This proactive approach to innovation ensures manufacturers remain competitive in the evolving global marketplace. Developing new sustainable materials and processes is crucial for creating truly environmentally responsible products.

Boosting Productivity and Efficiency Across the Board

Streamlining Workflow for Enhanced Efficiency

A key aspect of boosting productivity is streamlining workflows. This involves identifying bottlenecks and inefficiencies in existing processes. By analyzing current procedures and implementing changes, such as automating repetitive tasks or optimizing communication channels, businesses can significantly reduce wasted time and resources. This leads to a more efficient use of personnel and a more streamlined output, ultimately contributing to improved overall productivity.

Efficient workflows are crucial for maintaining a high level of productivity. They enable teams to focus on high-value tasks, leading to better results and greater overall efficiency. Implementing clear and concise procedures, along with proper delegation of responsibilities, is essential for achieving this. This proactive approach fosters a culture of efficiency, which in turn promotes growth and success.

Prioritizing Tasks and Managing Time Effectively

Effective time management is paramount to productivity. Understanding your priorities and allocating time accordingly can dramatically improve output. This involves breaking down large projects into smaller, more manageable tasks. Prioritizing these tasks based on their urgency and importance allows for a focused approach, avoiding distractions and maximizing efficiency.

Leveraging Technology for Automation and Optimization

Integrating technology into daily operations is crucial for boosting productivity. Software solutions can automate repetitive tasks, freeing up employees to focus on more strategic initiatives. By automating mundane tasks, employees can dedicate more time to higher-level projects, generating more innovative ideas and driving progress. This increased efficiency often results in a higher quality output, as employees are able to focus their energy on the most important aspects of their work.

Utilizing project management software, for example, allows for better task organization, streamlined communication, and improved collaboration among team members. This enhanced coordination fosters a more efficient and productive work environment, leading to better results and greater overall efficiency. These tools can significantly reduce the time spent on administrative tasks and increase the time dedicated to core responsibilities.

Cultivating a Positive and Supportive Work Environment

A positive and supportive work environment plays a significant role in boosting productivity and efficiency. Creating an atmosphere where employees feel valued, respected, and empowered to contribute their best work is essential. Open communication channels, constructive feedback, and recognition for accomplishments are fundamental elements of such an environment.

Investing in Training and Development

Investing in employee training and development is essential for improving productivity and efficiency. Providing opportunities for employees to enhance their skills and knowledge equips them to perform their tasks more effectively and efficiently. This leads to increased output, decreased errors, and a more engaged and motivated workforce.

Yeast infections, often characterized by vaginal discomfort, can manifest in various ways. Identifying the specific symptoms is crucial for accurate diagnosis and effective treatment. Common symptoms include itching, redness, and swelling of the vulva and vaginal area. A thick, white, cheesy discharge is another typical sign, though the discharge can sometimes be clear or watery. It's important to note that these symptoms can overlap with other conditions, making proper diagnosis essential.