The Impact on Operational Efficiency and Productivity

Improved Workflow Automation

Digital transformation initiatives often involve automating repetitive tasks, freeing up human employees to focus on higher-value activities. This automation not only reduces operational inefficiencies but also significantly boosts productivity. By leveraging software solutions and robotic process automation (RPA), companies can streamline workflows, eliminate manual data entry, and ensure consistent execution of processes. This leads to reduced errors, faster turnaround times, and a more agile response to changing business demands, ultimately leading to a substantial increase in overall output.

The streamlined workflow also facilitates better communication and collaboration across different teams and departments. Real-time data sharing and automated notifications ensure that everyone is informed and updated on the progress of tasks, leading to a more coordinated and efficient operation.

Enhanced Data Analysis and Decision-Making

Digital transformation provides companies with access to vast amounts of data, which can be leveraged to gain valuable insights into customer behavior, market trends, and operational processes. Advanced analytics tools allow for the identification of patterns and correlations, enabling businesses to make data-driven decisions. This enhanced data analysis capability leads to more effective strategies and targeted actions, ultimately impacting the bottom line positively.

By providing a comprehensive view of operational data, digital transformation facilitates more informed decision-making. This empowers managers to identify areas for improvement, optimize resource allocation, and refine strategies based on real-time insights, ultimately leading to improved profitability and efficiency.

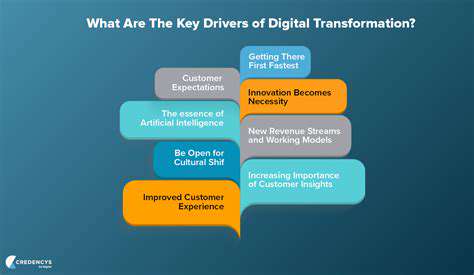

Increased Agility and Adaptability

In today's dynamic business environment, agility and adaptability are crucial for survival and success. Digital transformation enables organizations to respond quickly to market changes and customer demands. Cloud-based platforms and scalable software solutions allow for rapid deployment of new features and functionalities, enabling companies to adjust to evolving market trends and customer preferences more effectively. This flexibility enables organizations to seize new opportunities and navigate challenges with greater ease.

The ability to adapt quickly to changing demands is vital for maintaining a competitive edge. Digital transformation equips companies with the tools and technologies necessary to respond dynamically to market fluctuations, customer feedback, and emerging trends, ensuring long-term sustainability and growth.

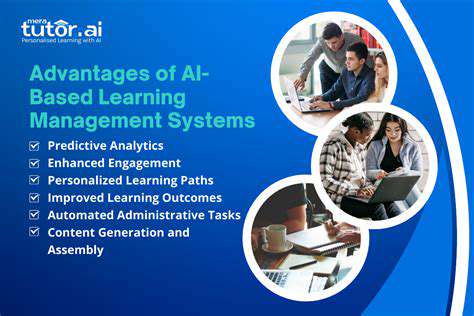

Improved Customer Experience

Digital transformation initiatives often lead to a more personalized and engaging customer experience. By leveraging customer relationship management (CRM) systems and data analytics, businesses can gain a deeper understanding of their customers' needs and preferences. This allows for the creation of targeted marketing campaigns, personalized product recommendations, and improved customer support, ultimately enhancing customer satisfaction and loyalty.

Enhanced Collaboration and Communication

Digital transformation fosters better collaboration and communication among employees, teams, and stakeholders. Collaboration tools, project management software, and instant messaging platforms facilitate seamless information sharing and real-time communication. This streamlined communication enhances teamwork, reduces misunderstandings, and improves overall efficiency within the organization. The enhanced ability to communicate effectively across different departments and geographical locations further strengthens the organization's ability to achieve its goals.

Reduced Operational Costs

Implementing digital solutions can lead to significant reductions in operational costs. Automation of tasks, optimization of resource allocation, and elimination of manual processes can result in substantial cost savings. Digital tools often provide a more efficient way to manage inventory, track expenses, and streamline supply chain operations, leading to reduced waste and increased profitability. The improved efficiency stemming from digital transformation translates to lower overhead expenses and increased overall profitability.

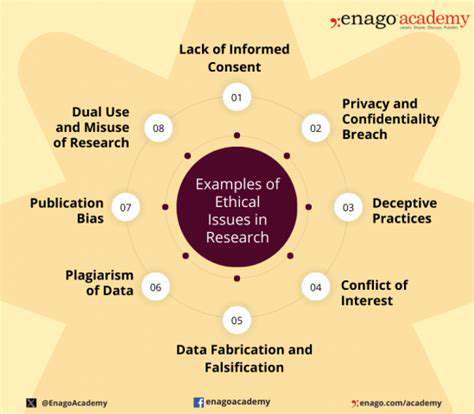

Security and Risk Management

Digital transformation necessitates robust security measures to protect sensitive data and prevent cyber threats. Implementing strong security protocols, data encryption, and access controls is crucial to maintain the integrity and confidentiality of information. By adopting advanced security measures, companies can safeguard their valuable assets and maintain the trust of their customers and partners, ensuring that digital transformation initiatives are implemented in a secure and responsible manner. The comprehensive approach to security and risk management is vital for the successful adoption of digital tools and processes.

Enhancing Agility and Adaptability in Manufacturing

Improving Operational Efficiency

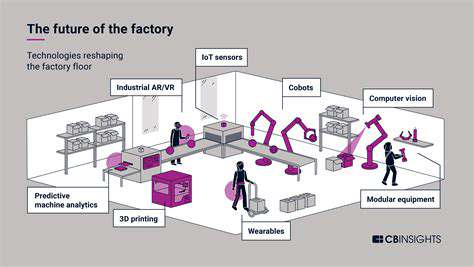

Digital transformation initiatives in manufacturing often focus on streamlining operations and increasing efficiency. Implementing advanced technologies like Industry 4.0 solutions, including IoT sensors, predictive maintenance algorithms, and automated guided vehicles (AGVs), can significantly reduce downtime and improve production output. These systems collect real-time data, allowing for proactive identification of potential issues, leading to faster problem resolution and minimized disruptions to the production line. This proactive approach not only enhances efficiency but also reduces the cost associated with unplanned downtime and maintenance.

Furthermore, integrating data analytics tools allows manufacturers to analyze vast amounts of production data to identify patterns, trends, and bottlenecks. This detailed analysis enables the optimization of processes, leading to improved resource allocation, reduced waste, and increased overall productivity. The ability to adapt manufacturing processes in real-time based on this data-driven insight is a key component of agility and adaptability in modern manufacturing.

Adapting to Changing Market Demands

The modern manufacturing landscape is characterized by fluctuating customer demands and evolving market trends. Digital transformation empowers manufacturers to respond quickly to these changes. By leveraging data analytics and agile methodologies, businesses can gain a deeper understanding of customer preferences and market dynamics. This allows for rapid adjustments to production plans, enabling the efficient production of customized products or quick shifts to meet emerging demands.

For example, companies can leverage digital platforms to analyze sales data, identify emerging trends, and adjust production schedules accordingly. This adaptability translates into improved customer satisfaction, faster time-to-market for new products, and a stronger competitive edge in the marketplace. This responsiveness to market changes is critical for maintaining a strong position within a dynamic and ever-evolving industry.

Enhancing Collaboration and Communication

Digital transformation fosters greater collaboration and communication throughout the entire manufacturing value chain. Cloud-based platforms and collaborative software tools enable seamless communication between different departments, suppliers, and customers. This enhanced communication streamlines workflows, reduces delays, and improves overall coordination. Effective communication is crucial for agile responses to unforeseen circumstances and for the successful implementation of new strategies.

Moreover, digital tools facilitate knowledge sharing and teamwork. The ability to quickly access and share critical information across the organization empowers employees to make informed decisions and contribute effectively to problem-solving. This collaborative environment fosters a culture of innovation and allows for faster adaptation to changing market conditions. This increased transparency and collaboration significantly enhances the responsiveness and adaptability of the entire manufacturing operation.

Leveraging Data for Informed Decision Making

Data-driven decision-making is crucial for enhancing agility and adaptability in manufacturing. Digital transformation provides manufacturers with access to an abundance of data from various sources, including machines, sensors, and customer interactions. This wealth of data can be analyzed to identify trends, predict future needs, and optimize production processes. By leveraging data analytics, manufacturers can gain a comprehensive understanding of their operations and make more informed decisions about resource allocation, process improvement, and product development.

Real-time data visualization tools allow manufacturers to monitor key performance indicators (KPIs) and identify potential issues proactively. This proactive approach enables quick adjustments to production schedules, resource allocation, and product design. Ultimately, this data-driven approach to decision-making fosters agility and adaptability, enabling manufacturers to respond quickly to market changes and customer needs.

The Future of Manufacturing and the Challenges Ahead

The Rise of Automation

Automation is rapidly transforming the manufacturing landscape, with robots and AI taking on increasingly complex tasks. This shift is leading to increased efficiency and productivity, allowing manufacturers to produce goods at a faster pace and with greater precision. The integration of automation is crucial for staying competitive in the global market. Furthermore, automation frees human workers from repetitive and hazardous tasks, allowing them to focus on higher-level responsibilities and innovation.

The implementation of sophisticated robotic systems, coupled with advanced machine learning algorithms, is enabling manufacturers to achieve unprecedented levels of accuracy and consistency in their processes. This advancement in automation is not just about replacing human labor, but about augmenting it, creating a collaborative environment where humans and machines work together to achieve common goals.

Sustainable Manufacturing Practices

Environmental consciousness is driving a significant shift towards sustainable manufacturing practices. Companies are increasingly prioritizing resource efficiency, waste reduction, and the use of recycled materials. This commitment to sustainability not only mitigates the environmental impact of manufacturing but also creates a competitive advantage in the market. Consumers are increasingly aware of the environmental footprint of products, demanding more sustainable alternatives.

Implementing circular economy principles, where materials are reused and recycled, is crucial. Companies are exploring innovative approaches to reduce their carbon footprint, such as using renewable energy sources and optimizing energy consumption within their facilities.

Digitalization and Data-Driven Decision Making

The digitalization of manufacturing processes is enabling real-time data collection and analysis. This data-driven approach allows manufacturers to optimize their operations, predict potential issues, and make informed decisions about resource allocation and production strategies. Manufacturers are leveraging data analytics to identify trends and patterns, enabling them to proactively address challenges and improve overall efficiency.

Advanced technologies, such as the Internet of Things (IoT), are connecting various components of the manufacturing process. This interconnectedness provides a wealth of data that can be used to monitor equipment performance, predict maintenance needs, and optimize production schedules.

The Importance of Skilled Labor

Despite the rise of automation, skilled labor remains crucial to the future of manufacturing. The need for skilled workers with expertise in areas such as robotics, AI, and data analysis is growing rapidly. Training and development programs are essential to equip workers with the necessary skills to thrive in this evolving landscape. Manufacturers must invest in education and training programs to ensure a skilled workforce to operate and maintain the advanced technologies.

The focus should shift from simply replacing human labor to upskilling and reskilling existing workers to work alongside these new technologies. This collaborative approach will ensure that the workforce is equipped to leverage the power of automation and data analytics effectively.

Supply Chain Resilience and Global Interdependence

The interconnected nature of global supply chains presents both opportunities and challenges. Manufacturers must prioritize resilience and adaptability in their supply chains to navigate disruptions and maintain smooth operations. Diversification of suppliers and development of alternative logistics routes are crucial for mitigating risks associated with geopolitical instability. This resilience ensures production continuity even when disruptions occur.

Globalization brings with it the imperative of ethical sourcing and responsible labor practices. Transparency and accountability throughout the supply chain are essential for building trust with consumers and stakeholders. This commitment to ethical practices supports a sustainable and equitable future for all.

The Role of Innovation and Research and Development

Continuous innovation is essential for maintaining a competitive edge in the dynamic manufacturing sector. Investing in research and development (R&D) is critical to developing new technologies, processes, and materials that drive efficiency and sustainability. This investment in innovation allows manufacturers to adapt to changing market demands and customer preferences.

Collaboration between manufacturers, universities, and research institutions is vital to foster a culture of innovation. The sharing of knowledge and resources accelerates the development of new solutions and technologies, benefiting the entire manufacturing ecosystem.