Enhanced Operational Visibility and Control

Real-time Data Monitoring for Enhanced Decision-Making

Real-time data streaming from connected devices within an industrial environment provides unparalleled insights into operational parameters. This continuous flow of information enables proactive identification of potential issues, such as equipment malfunctions or process deviations, allowing for swift corrective actions. By visualizing key performance indicators (KPIs) in real-time dashboards, operators can quickly assess the overall health of the system and make informed decisions to optimize efficiency and minimize downtime.

Furthermore, this constant stream of data allows for advanced predictive analytics, enabling proactive maintenance scheduling and reducing unexpected breakdowns. This predictive capability translates directly into increased operational efficiency and reduced maintenance costs.

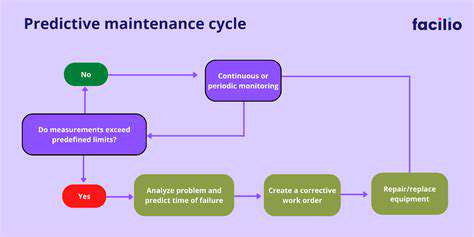

Improved Predictive Maintenance Strategies

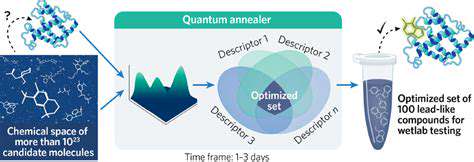

Predictive maintenance is a crucial aspect of optimizing operations in industrial settings. By analyzing historical data, current operational parameters, and sensor readings, IIoT platforms can anticipate equipment failures before they occur. This proactive approach minimizes costly downtime by scheduling maintenance interventions when most beneficial, thus reducing unplanned shutdowns and optimizing production schedules. The ability to predict potential failures enables a more strategic and efficient allocation of maintenance resources.

Automated Process Optimization

IIoT systems empower businesses to automate various processes, resulting in significant efficiency gains. Automated adjustments to parameters like temperature, pressure, and flow rates, based on real-time data analysis, ensure optimal performance and consistent quality output. This automation reduces the need for manual intervention, minimizing human error and increasing production output.

Automated processes also free up personnel for higher-level tasks, enabling them to focus on innovation and strategic planning rather than mundane, repetitive tasks.

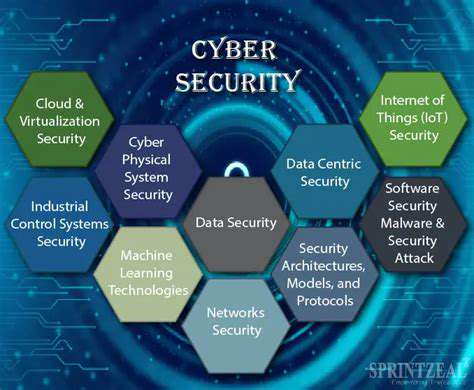

Enhanced Security Measures for Industrial Data

As industrial networks become increasingly interconnected, the need for robust security measures is paramount. IIoT platforms need to incorporate advanced security protocols to protect sensitive data from unauthorized access and cyber threats. This includes encryption, secure communication channels, and multi-factor authentication. Implementing these measures safeguards critical operational data and prevents disruptions to the production process.

Remote Monitoring and Control Capabilities

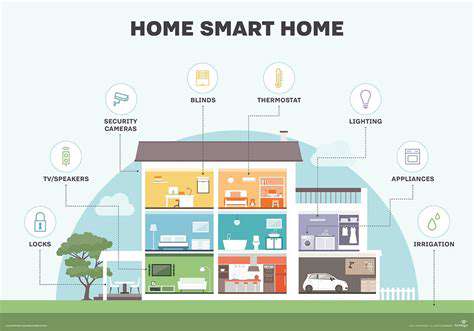

IIoT enables remote monitoring and control of industrial equipment and processes, regardless of geographical location. This capability provides significant advantages, such as increased accessibility and flexibility. Operators can monitor and manage operations from anywhere with an internet connection, leading to improved responsiveness to issues and faster resolution times. This remote access is invaluable for geographically dispersed operations.

Real-Time Collaboration and Knowledge Sharing

IIoT fosters real-time collaboration and knowledge sharing among different departments and personnel within an organization. The system facilitates seamless communication and data exchange, enabling faster problem-solving and knowledge dissemination throughout the organization. This interconnectedness promotes a culture of continuous improvement and innovation, allowing for the rapid dissemination of best practices and lessons learned across the entire industrial network.

Reduced Operational Costs Through Efficiency Gains

The implementation of IIoT solutions often leads to significant reductions in operational costs. By optimizing energy consumption, reducing waste, and minimizing downtime, businesses can achieve substantial cost savings. The improved efficiency of operations translates directly into cost reductions, making IIoT a highly attractive investment for industrial organizations seeking to enhance profitability and competitiveness.

The Future of Industrial Automation: IIoT and Beyond

The Rise of Industrial IoT (IIoT)

Industrial IoT (IIoT) is rapidly transforming manufacturing and industrial processes, enabling unprecedented levels of connectivity and data collection. This interconnected network of devices, sensors, and software applications allows for real-time monitoring of equipment performance, predictive maintenance, and optimized resource allocation. The ability to collect and analyze vast quantities of data from various sources within the industrial environment is driving significant improvements in operational efficiency, productivity, and safety. This data-driven approach empowers businesses to make informed decisions, identify potential issues before they become critical, and ultimately, achieve a higher level of control over their industrial operations. The potential for increased automation and reduced downtime is substantial, making IIoT a cornerstone of modern industrial practices.

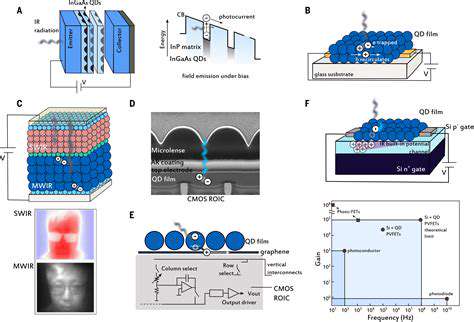

The integration of advanced sensors and actuators into industrial machinery allows for detailed monitoring of critical parameters, such as temperature, pressure, vibration, and flow rates. This granular level of data collection provides a comprehensive understanding of equipment health, enabling proactive maintenance scheduling and minimizing unplanned downtime. Furthermore, the interconnected nature of IIoT systems enables the development of intelligent control systems, leading to optimized processes and enhanced operational efficiency. This detailed understanding of the intricacies of the industrial process allows for precise control and adjustment, maximizing productivity and minimizing waste.

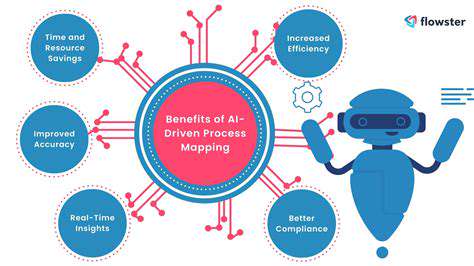

Beyond IIoT: Emerging Trends in Automation

While IIoT forms the foundation of modern industrial automation, the future extends beyond the current scope. Emerging technologies, such as artificial intelligence (AI) and machine learning (ML), are poised to further revolutionize industrial processes. AI-powered systems can analyze vast amounts of data collected by IIoT networks to identify patterns, predict equipment failures, and optimize production schedules. This predictive capability not only minimizes downtime but also allows manufacturers to proactively adjust their operations to maximize efficiency and profitability.

The integration of robotics and automation is another key trend. Collaborative robots (cobots), designed to work alongside human operators, are becoming increasingly common in industrial settings. These cobots can handle repetitive tasks, improve safety, and enhance productivity. The combination of IIoT data with advanced robotics promises to create even more sophisticated and adaptable automated systems, capable of handling complex tasks and optimizing processes in ways previously unimaginable.

Furthermore, the concept of Industry 4.0, encompassing the integration of cyber-physical systems (CPS) and digital twins, is gaining traction. Digital twins provide virtual representations of physical assets and processes, enabling simulation and optimization before implementation in the real world. This predictive capability allows manufacturers to test and refine strategies for improved performance and resource utilization, leading to more sustainable and efficient industrial operations. The marriage of IIoT, AI, robotics, and digital twins promises to usher in a new era of industrial automation.

The seamless integration of these technologies will lead to more intelligent and adaptive systems, enabling manufacturers to respond quickly to changing market demands and production needs. This adaptability will be crucial for maintaining competitiveness in a rapidly evolving global marketplace.

The continuous evolution of software and communication technologies is also critical. Robust, secure, and scalable communication protocols are essential for enabling seamless data exchange between devices and systems. This will ensure the reliability and stability of the entire IIoT ecosystem.