Predictive Maintenance: Anticipating Failures

Predictive Maintenance: Understanding the Concept

Predictive maintenance (PdM) is a proactive approach to maintenance that aims to predict equipment failures before they occur. This differs significantly from reactive maintenance, which only addresses failures after they have happened. By analyzing data from various sources, PdM seeks to identify patterns and indicators that signal potential problems, enabling maintenance teams to intervene before significant damage or downtime occurs. This proactive strategy ultimately leads to reduced costs and improved operational efficiency.

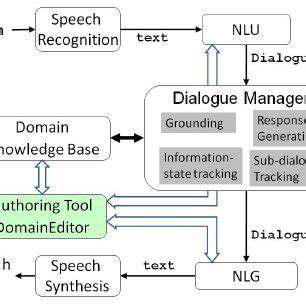

The core principle of PdM is the utilization of advanced data analytics and machine learning techniques. These powerful tools allow for the identification of subtle anomalies and trends within equipment data, which can be missed by traditional methods. By extracting valuable insights from historical data, sensor readings, and other operational information, PdM systems can anticipate potential failures and schedule maintenance accordingly.

Benefits of Predictive Maintenance

The advantages of implementing PdM are numerous and impactful. Reduced downtime is a key benefit, as maintenance can be scheduled in advance, avoiding unexpected equipment failures and subsequent production halts. This translates directly into increased operational efficiency and higher productivity levels. Moreover, PdM helps to minimize costly repairs and replacements by addressing potential issues early on, avoiding further deterioration and potential catastrophic failures.

Predicting equipment failures before they occur allows for proactive maintenance, significantly reducing overall maintenance costs. The cost savings extend beyond repair costs, also encompassing reduced parts replacement and labor expenses.

Data Sources for Predictive Maintenance

PdM relies on a variety of data sources to develop accurate predictions. These sources can include sensor data from machines, operational logs, and even weather patterns that might indirectly impact equipment performance. By combining data from diverse sources, PdM systems can paint a more comprehensive picture of the equipment's health and potential failure points.

Sophisticated algorithms analyze this data to identify patterns and anomalies, allowing for the generation of predictive models. Data quality and consistency are critical for accurate predictions. Robust data management and collection strategies are essential for the success of any PdM implementation.

Implementing Predictive Maintenance Systems

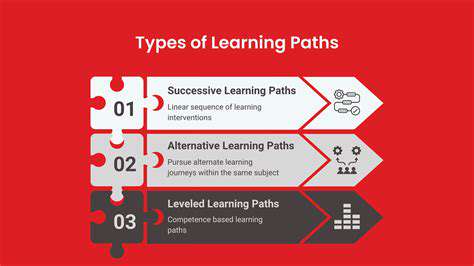

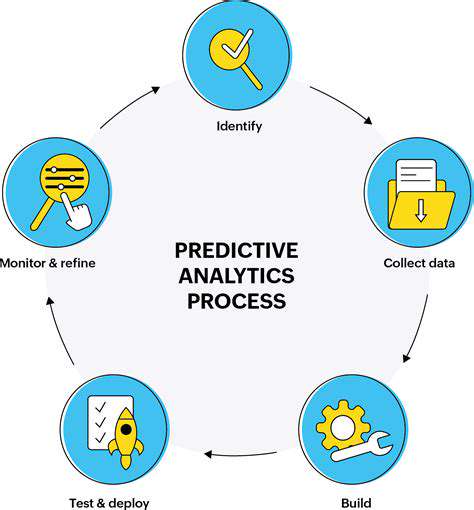

Implementing a PdM system requires careful planning and execution. The first step is to identify the equipment that will be monitored and the data sources that will be utilized. This involves a thorough assessment of the specific needs and characteristics of the equipment in question.

Careful consideration needs to be given to data collection strategies and the selection of appropriate analytical tools. Choosing the right data analytics software and ensuring data integrity are vital steps in the implementation process. Training of personnel to interpret the insights generated by the system is also crucial for successful adoption.

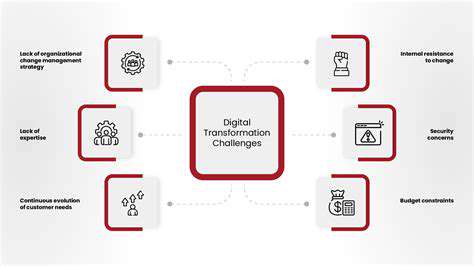

Challenges of Predictive Maintenance

While PdM offers significant benefits, there are also challenges to consider. One significant hurdle is the need for significant upfront investment in data acquisition systems, analytical tools, and trained personnel. The complexity of some systems can also pose challenges, requiring specialized expertise for implementation and management.

Another challenge lies in the need for accurate and reliable data. Data quality issues, such as missing or inconsistent data points, can negatively impact the accuracy of predictive models and lead to inaccurate predictions. Ensuring data integrity is critical for effective PdM systems.

The Future of Predictive Maintenance

The field of predictive maintenance is continuously evolving, with advancements in machine learning and AI playing a key role. As data collection and processing capabilities improve, PdM systems will become even more sophisticated and effective. The future promises even more accurate predictions and a greater degree of proactive maintenance, further optimizing industrial processes and reducing operational costs.

The integration of PdM with other technologies, such as IoT and cloud computing, is expected to further enhance its capabilities and expand its applications across various industries. This will lead to more comprehensive and automated maintenance strategies, further improving efficiency and safety.

Selecting the appropriate winter gear for your furry friend is crucial for their comfort and well-being in cold weather. Consider factors like their breed, coat type, and activity level. A short-haired dog might need a thicker, more insulated coat than a dog with a double coat. Additionally, dogs who spend significant time outdoors, playing vigorously, or have underlying health conditions requiring extra warmth will need more substantial winter protection.

The Future of Smart Manufacturing

The Rise of Predictive Maintenance in IoT-Enabled Smart Factories

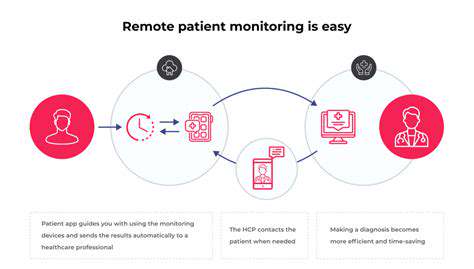

Smart manufacturing, fueled by the Internet of Things (IoT), is rapidly transforming industrial landscapes. A critical component of this transformation is predictive maintenance, allowing manufacturers to anticipate equipment failures before they occur. This proactive approach minimizes downtime, reduces repair costs, and optimizes operational efficiency. The integration of sensors and data analytics within IoT platforms allows for real-time monitoring of equipment health, enabling businesses to identify potential issues and schedule maintenance proactively.

By leveraging historical data, real-time sensor readings, and machine learning algorithms, smart factories can create predictive models that accurately forecast equipment lifecycles. This capability provides manufacturers with a significant advantage in the competitive marketplace.

Data-Driven Insights for Optimized Production

The vast amounts of data generated by IoT-connected machines in a smart factory provide a goldmine of information. Analyzing this data allows manufacturers to gain deep insights into production processes, identify bottlenecks, and optimize workflows. By understanding patterns and anomalies in the data, manufacturers can fine-tune production schedules, improve resource allocation, and ultimately, enhance overall productivity.

Enhanced Safety and Reduced Risks Through Proactive Monitoring

Real-time monitoring of equipment health through IoT sensors can significantly enhance safety in the manufacturing environment. Predictive maintenance systems can detect early warning signs of potential hazards, such as equipment overheating or structural weaknesses. This proactive approach allows for timely interventions to prevent accidents and minimize risks to personnel and the facility.

Furthermore, by identifying potential risks early on, manufacturers can implement preventative measures to reduce the likelihood of costly incidents and ensure a safer working environment.

Improving Operational Efficiency and Reducing Costs

Predictive maintenance, enabled by IoT, directly translates into improved operational efficiency. By minimizing unplanned downtime, manufacturers can streamline production processes, improve delivery times, and ultimately reduce operational costs. The ability to anticipate and address equipment failures before they impact production schedules significantly increases the efficiency of the entire manufacturing operation.

Reduced maintenance costs, fewer emergency repairs, and optimized resource allocation all contribute to a substantial reduction in overall operating expenses.

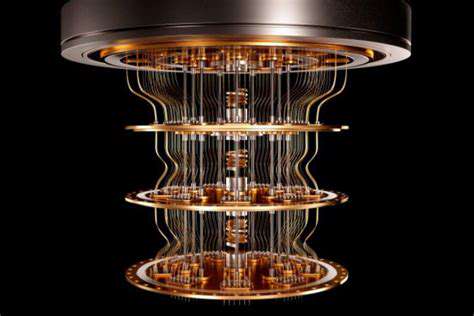

The Integration of Artificial Intelligence (AI) for Enhanced Accuracy

AI plays a crucial role in enhancing the accuracy and effectiveness of predictive maintenance models. AI algorithms can analyze complex data patterns, identify subtle anomalies, and provide more accurate predictions of equipment failures. This integration significantly increases the reliability and trustworthiness of the predictive maintenance system, allowing manufacturers to make more informed decisions regarding maintenance schedules.

The use of AI in conjunction with IoT data creates a powerful synergy that elevates predictive maintenance to a new level of sophistication and precision.

The Importance of Secure Data Management in Smart Factories

Protecting the sensitive data generated by IoT devices is paramount in smart manufacturing environments. Robust security measures are essential to prevent unauthorized access and data breaches, maintaining the confidentiality and integrity of the data used for predictive maintenance. This includes implementing encryption protocols, access controls, and regular security audits to safeguard against cyber threats and ensure the reliability of the system.

Data breaches can have severe consequences, including financial losses, reputational damage, and operational disruption. A strong security posture is essential for the long-term success of any smart factory.

Future Trends and Innovations in Smart Manufacturing

The future of smart manufacturing is poised for even greater advancements in predictive maintenance. Expect to see further integration of advanced technologies such as machine learning, deep learning, and edge computing, enhancing the capabilities of predictive models. Remote diagnostics and automated maintenance procedures will also become increasingly common, further reducing downtime and improving operational efficiency.

The continuous evolution of IoT and AI will drive innovation in smart manufacturing, enabling manufacturers to achieve unprecedented levels of efficiency and productivity in the years to come.