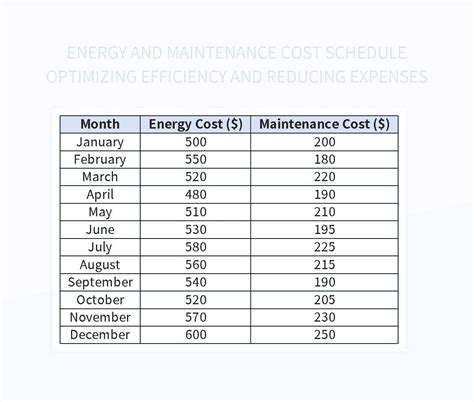

Optimizing Maintenance Schedules and Reducing Costs

Preventive Maintenance Strategies

Preventative maintenance programs form the backbone of efficient equipment management, emphasizing early intervention to avoid major malfunctions. Implementing comprehensive PM protocols involves systematic inspections, routine servicing, and timely replacement of critical parts to ensure optimal performance and longevity. This forward-thinking approach dramatically cuts unexpected downtime while preventing severe equipment failures. Standard PM activities include lubrication routines, cleaning procedures, and detailed component examinations.

Creating customized PM schedules for specific equipment requires careful consideration of operating conditions, usage frequency, and manufacturer specifications. This tailored methodology guarantees that maintenance occurs at precisely the right intervals to maximize reliability while minimizing service expenditures.

Predictive Maintenance Techniques

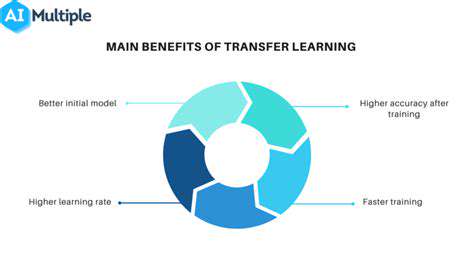

Predictive maintenance represents the next evolutionary step beyond traditional approaches, employing sensor data and analytics to forecast equipment issues. This method tracks performance metrics to detect early indicators of component degradation. Identifying these warning signals enables preemptive maintenance scheduling, optimizing equipment availability while extending service life.

Effective predictive maintenance implementation requires installation of monitoring sensors that track vibration levels, temperature fluctuations, and pressure variations. Advanced analytical tools process this data to identify patterns and predict potential failures, allowing for exceptionally precise maintenance planning that further reduces operational costs.

Impact of Maintenance on Operational Efficiency

Well-structured maintenance programs directly enhance operational performance. By maximizing equipment availability and minimizing unplanned outages, organizations achieve substantial production improvements with reduced operating expenses. Optimized maintenance scheduling ensures consistent, reliable equipment operation, resulting in smoother production flows and higher output levels. Properly timed maintenance also decreases the likelihood of expensive production errors and delivery delays.

Efficient maintenance scheduling contributes to leaner operations by eliminating unnecessary downtime. These efficiency gains translate directly to bottom-line improvements through cost reductions and productivity enhancements. Businesses that prioritize maintenance optimization typically experience measurable operational improvements.

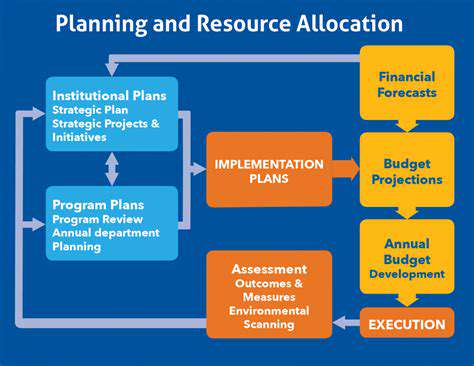

Establishing a Robust Maintenance Management System

A comprehensive maintenance management platform proves essential for implementing and overseeing optimized service schedules. This system should integrate all maintenance functions including planning, execution tracking, reporting, and analysis. Seamless integration with other operational systems ensures effective cross-departmental coordination and information sharing.

Centralized data handling and reporting capabilities form critical components of an effective maintenance management solution. These features enable comprehensive activity tracking, trend identification, and data-driven decision making for future maintenance planning. Clear communication protocols and standardized processes ensure all maintenance personnel understand their specific roles and obligations, fostering consistency and efficiency throughout the maintenance lifecycle.

Optimizing Maintenance Costs

Strategic maintenance scheduling generates significant cost savings by reducing emergency repairs, prolonging equipment lifespan, and implementing preventative measures. A well-structured maintenance program proves indispensable for controlling expenses while optimizing resource allocation.

Efficient maintenance planning allows for better utilization of both personnel and materials, yielding long-term financial benefits. By preventing catastrophic failures and optimizing service intervals, organizations achieve substantial reductions in their maintenance expenditures, implementing a far more economical approach to equipment management.